Disassembleable Stool - Product Design

Class prompt was to build a piece of furniture given material restraints: one 4' by 4' piece of plywood, and two 2' by 4' beams. I created a stool that could be disassembled and pieced together without tools or screws by designing a custom joinery technique.

COURSE: DES 135A / PRODUCT DESIGN

Tools: Sketching, Prototyping, Wood cutting

Timeframe: 4 weeks (February 2017)

Collapsed form (left): The four legs of the stool fit snugly together within three screws. The user is able to then grab onto the bottom of the stacked legs and carry all the pieces together for easy transport. Assembly (right): The legs come apart and fit into precisely cut grooves within the stool base, locking into place for ultimate sturdiness.

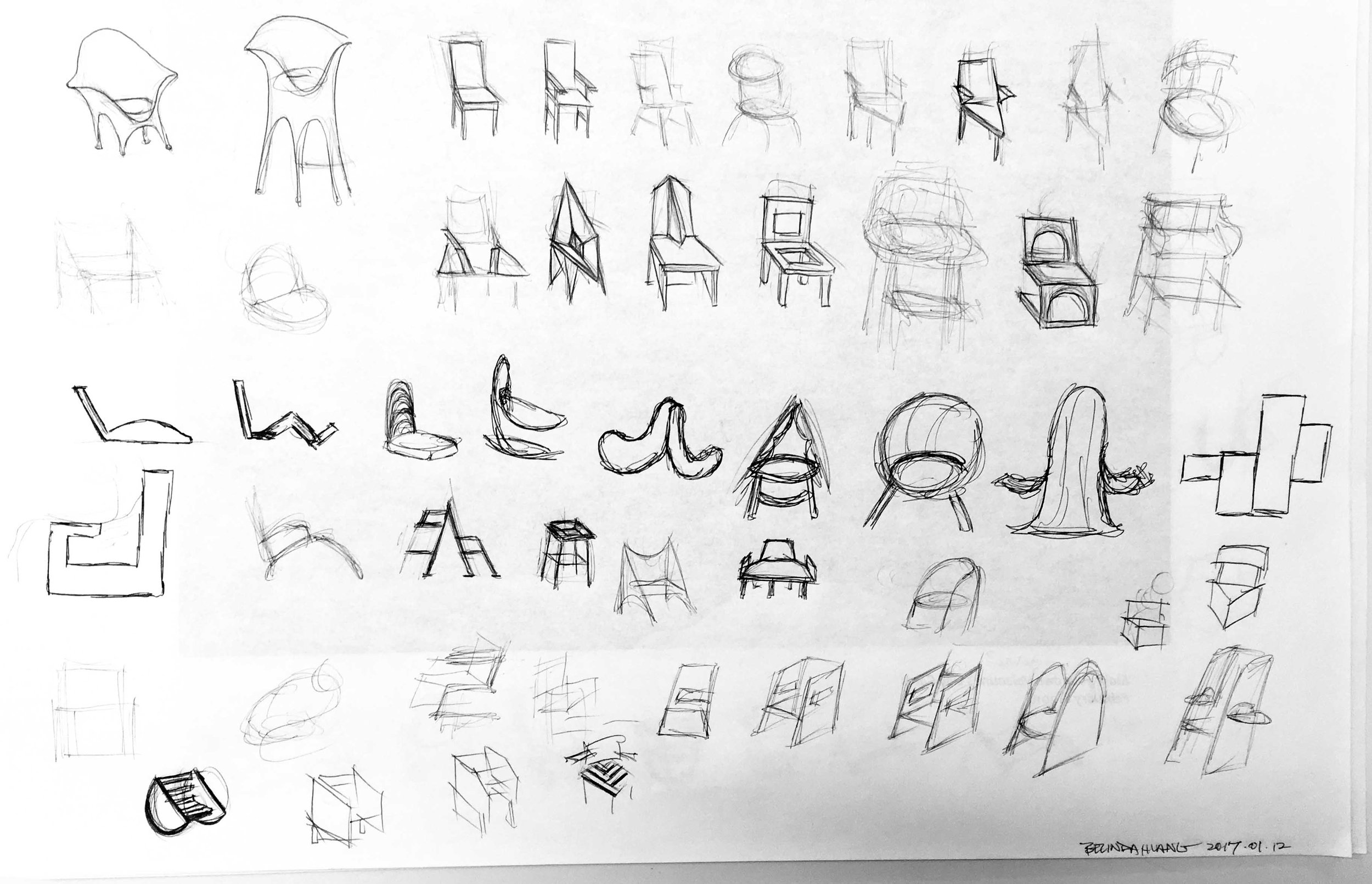

Ideation:

We were given the option of designing a chair or a table. I chose to do a chair. Our first exercise in class was to do five sketches in two minutes, then we shared papers with a classmate, and finished with 100+ rapid sketches of possible designs in the next 7 minutes, thinking outside conventional standards for furniture, targeting a specific need/audience, and practicing with various constraints. This brainstorming allowed for risk-free consideration of many possibilities to keep the idea door propped open. I thought that I was going at a good rate in the beginning until I learned that I needed to be even faster and less detailed with each thumbnail sketch. Was very happy that I got to 100.

Scale Model

(Left below) This prototype was constructed of a 4”x4” square of cardboard and the scaled equivalent of two 2x4’s (without the thickness). I liked this design because it was able to utilize every single piece of material we were given, and the cross-section footing made for extra stability. Unfortunately, once I brought it to the woodshop later and saw what an actual piece of 2x4 looked like, I realized the panels in the middle would be far thicker than I anticipated, so I scrapped this.

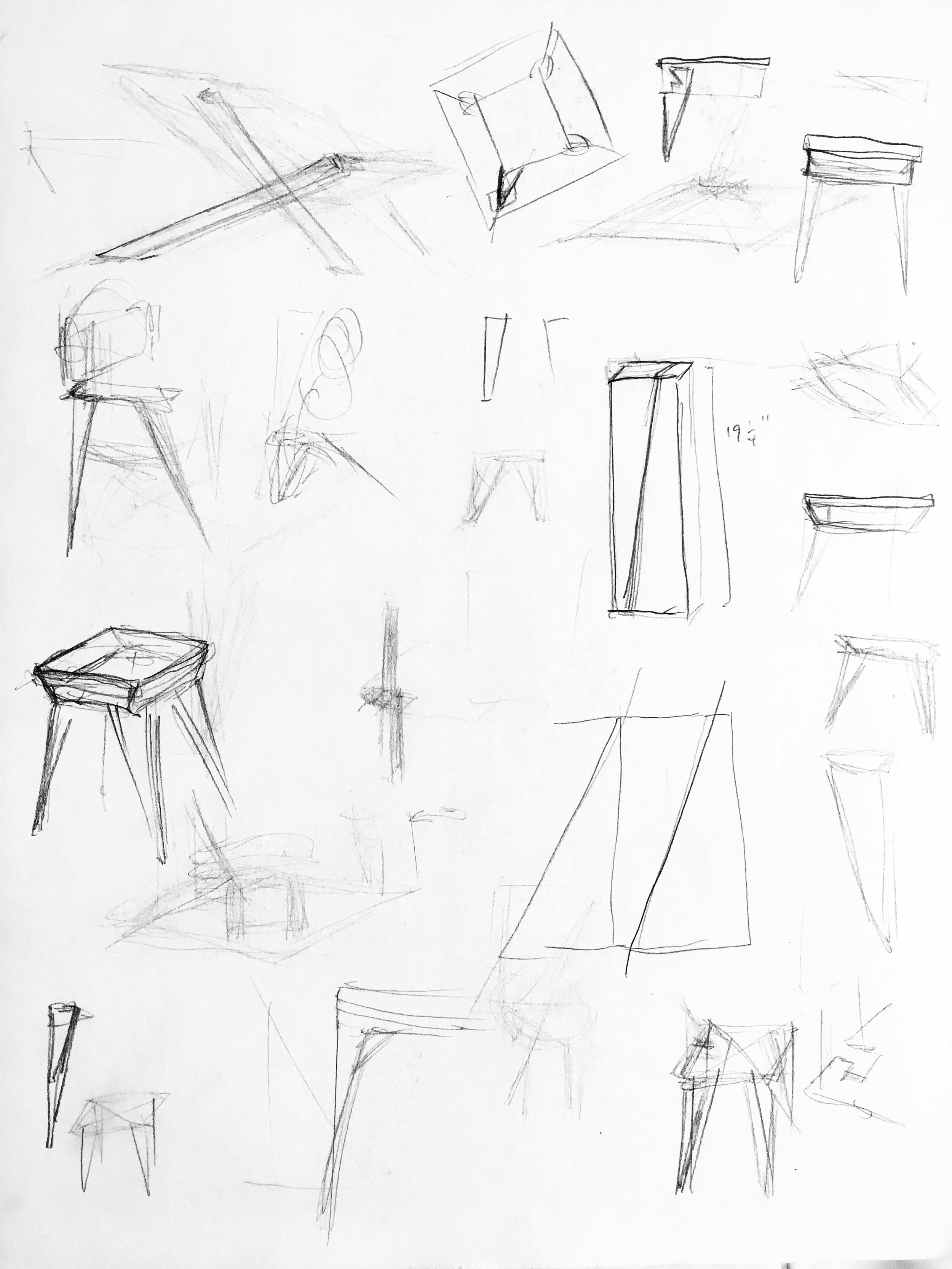

(Above) The sketches I brought in took full advantage of the materials we were allotted. I tried to create designs that would use the entire sheet of plywood, or minimal 2x4. This next set goes back to the conceptual designs: the Polite Chair was going to be a “standard chair” but with slight angle changes to force the user to sit with their legs closed and back straight.

Good idea, but too ambitious for the single week we had to build this, and I was still getting familiar with the power tools and wood cutting machines. Another idea placed on the back burner.

Change of plans

My professor had brought in a stool from IKEA that he wanted us to see. I became inspired by the joinery technique of the furniture that required no additional pieces/tools to put together: it locked with a very intricate pattern cut into the legs and the base. Got very excited about coming up with my own screw-less joinery designs.

Two things I was sure of:

The stool will have a flat plywood seat, no screws visible from top

- The legs will be removeable and reassemble-able

In order to lock into the seat, the legs would have to be angled. The underside of the seat would have to have a notch that would allow a notched leg to fit inside and push against the flat seat. Following the general securing tactic -----> I did most of my drawing on wood, using a scrap piece of 2x4 that I cut at an angle on the bandsaw. The stools in the woodshop are 16” in diameter so I used this sizing for the sides of the square seat.

construction

I spent a lot of time debating whether to go with something that needed high technical precision, or something that was stronger conceptually, but I decided for this first project, practicing getting the right cuts would have a higher payoff. (Bottom left) First cuts made on the 2x4 at a 45° angle on the miter saw. This would create the frame of the seat. Long size (outer edge) measured at 16”. I used the bandsaw to cut the 2x4’s at a 15° angle, freehanded.

Assembly

This stool can hold a human when legs are angled and secured. If I were to do this again, I’d make sure all the pieces join together effortlessly. Better planning and more beginner’s confidence would have allowed for more proper time allocation. Many lessons were learned.